Splices shall be made by certified trained personnel using approved equipment and procedures.

U.S. Army Corps of Engineers CEGS-03250

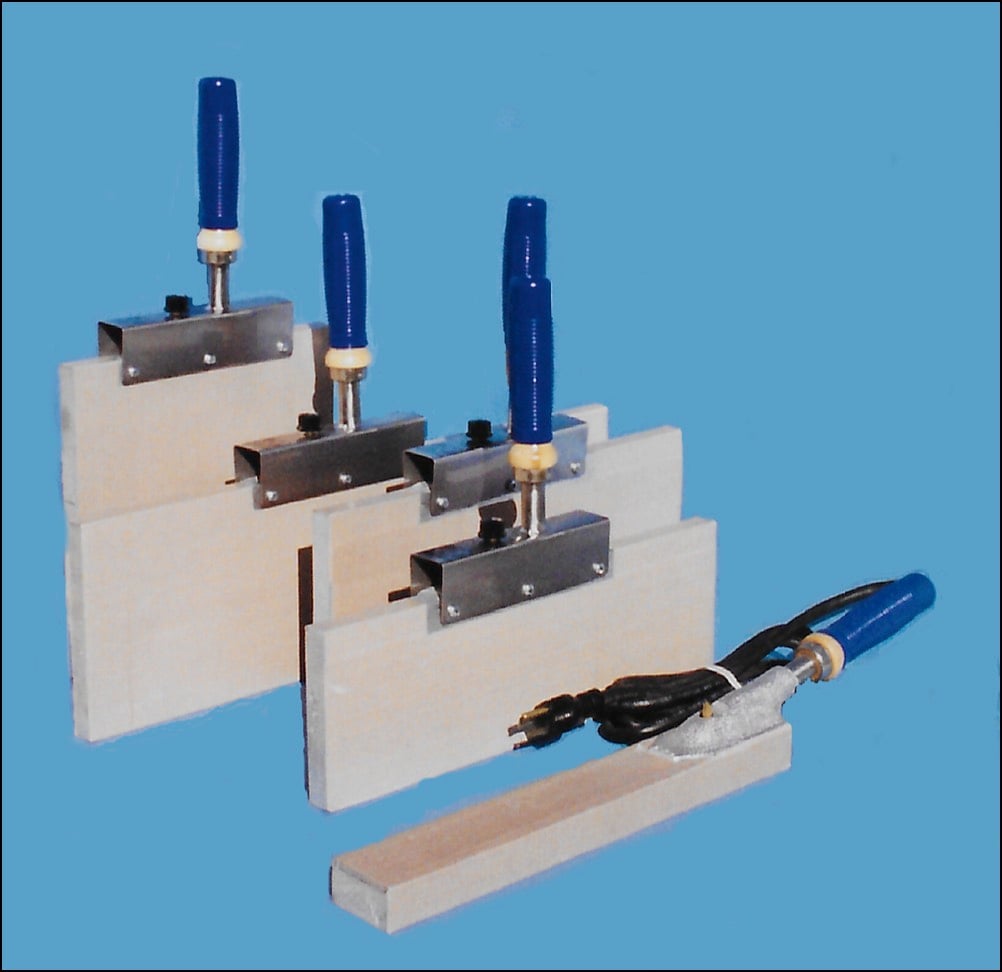

Waterstop Splicing Irons

JPS Standard Irons are specifically designed for welding waterstops, and other thermoplastic extruded profiles (expansion joints, seals). The temperature control can be adjusted from 250°F to 500°F to accommodate various ambient conditions and different polymers. All JPS Standard Irons are constructed with the highest quality components.- Peel and Stick Teflon® Cover included

- Heavy-duty vinyl grip and wood handle

- 8-foot, CSA & UL certified, outdoor use power cable

- Adjustable temperature with “Off” position

Small Waterstop Splicing Iron

Our most popular waterstop splicing iron. The JP214 is small and lightweight, and capable of welding all but the largest waterstop profiles.

12214 part number 110 volts 1”x2”x14”

12415 part number 220 volts 1”x2”x14”

Large Waterstop Splicing Irons

Large waterstop irons for large profiles.

12414 part number 110 volts .75”x4.5”x14”

12415 part number 220 volts .75x4.5”x14”

12614 part number 110 volts .75”x6”x14”

12615 part number 220 volts .75”x6”x14”

12620 part number 110 volts .75”x6”x20”

12621 part number 220 volts .75”x6”x20”

12919 part number 110 volts .75”x9”x9”

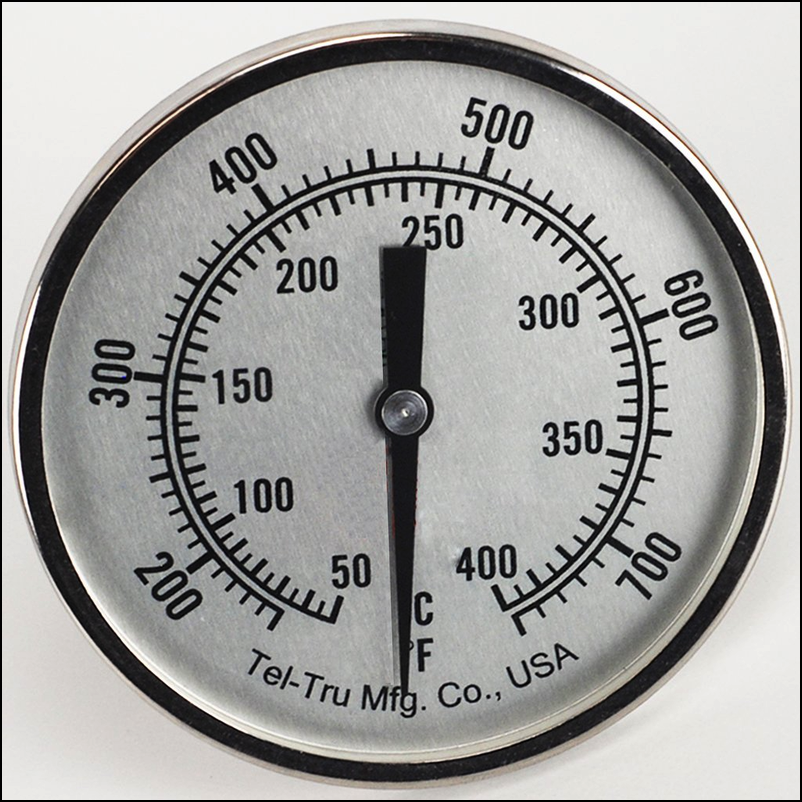

***ADD-ON*** JPS Analog Thermometer

Analog thermometer add-on for JPS standard waterstop splicing irons. Displays the correct temperature for welding thermoplastic waterstops and expansion joints. Dual-Gauge (Celsius and Fahrenheit) Temperature range: 150°F to 750°F.

12150 part number fits 12414, 12415, 12614, 12615, 12620, 12621, and 12919

Analog thermometer add-on for JPS standard waterstop splicing irons. Displays the correct temperature for welding thermoplastic waterstops and expansion joints. Dual-Gauge (Celsius and Fahrenheit) Temperature range: 150°F to 750°F.

12150 part number fits 12414, 12415, 12614, 12615, 12620, 12621, and 12919

Peel and Stick Teflon Covers

We factory cut our high-quality Teflon® replacement covers, so all you have to do is peel off the release paper and adhere it to the warm iron. No trimming is required.12213 part number fits JP214 iron

12413 part number fits JP414 iron

12613 part number fits JP614 iron

12619 part number fits JP620 iron

12918 part number fits JP919 iron

Tapper 1000 Tool

Used for installing Tapper® fasteners with various Earth Shield® Retrofit Waterstop Systems.11120 part number

Factory Installed Eyelets

Secure your waterstop 12” on-center with factory-installed brass eyelets. Eliminates all of the labor associated with hog rings.EY part number prefix existing waterstop part numbers (e.g. JP636 becomes EYJP636)

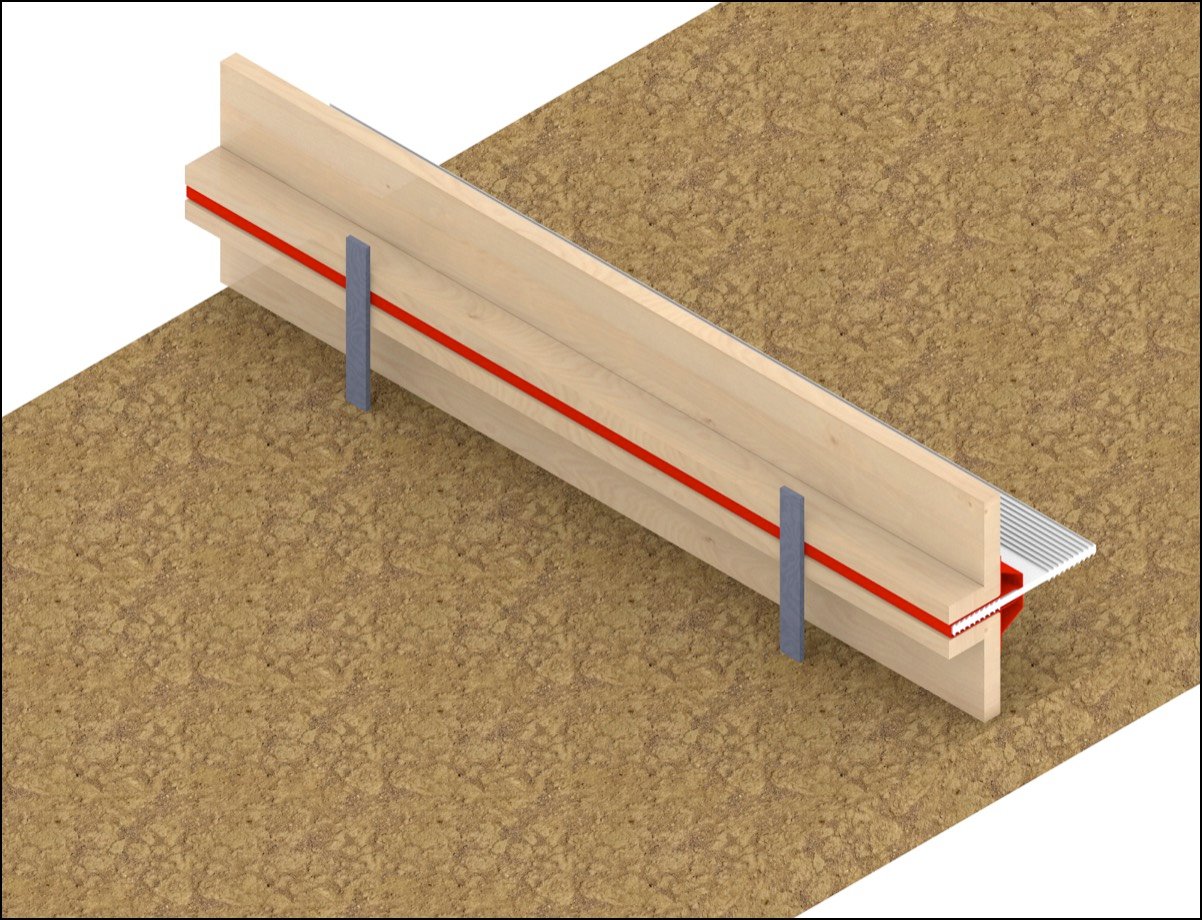

Waterstop Keycup

Keycup™ is a multi-function, reusable concrete accessory that is used to securely hold waterstop in place while simultaneously creating a keyed construction joint.Keycup1 part number 2" x 120" waterstop keycup

Keycup2 part number 3" x 120" waterstop keycup

Keycup2 part number 3" x 120" waterstop keycup

For more information visit Keycup.

Pro Built Waterstop Splicing Irons

Designed for the waterstop pro! Our Pro Series irons feature all the same attributes as our regular irons plus built-in thermometer, temperature control knob, outdoor-use power cord (UL and CSA approved), ergonomic vinyl grip, sealed elements, and a Silverstone coating that doesn't require covers.- Built-in analog thermometer

- Sealed end caps (meets EU Standards)

- Silverstone-coated — No Teflon® covers required

- Better, ergonomic handgrip

- 8-foot, CSA & UL certified, outdoor use power cord

- Meets CEGS 03250 requirements

12217 part number 220 volts 1”x2”x14”

12416 part number 110 volts .75”x4.5”x14”

12417 part number 220 volts .75"x4.5”x14”

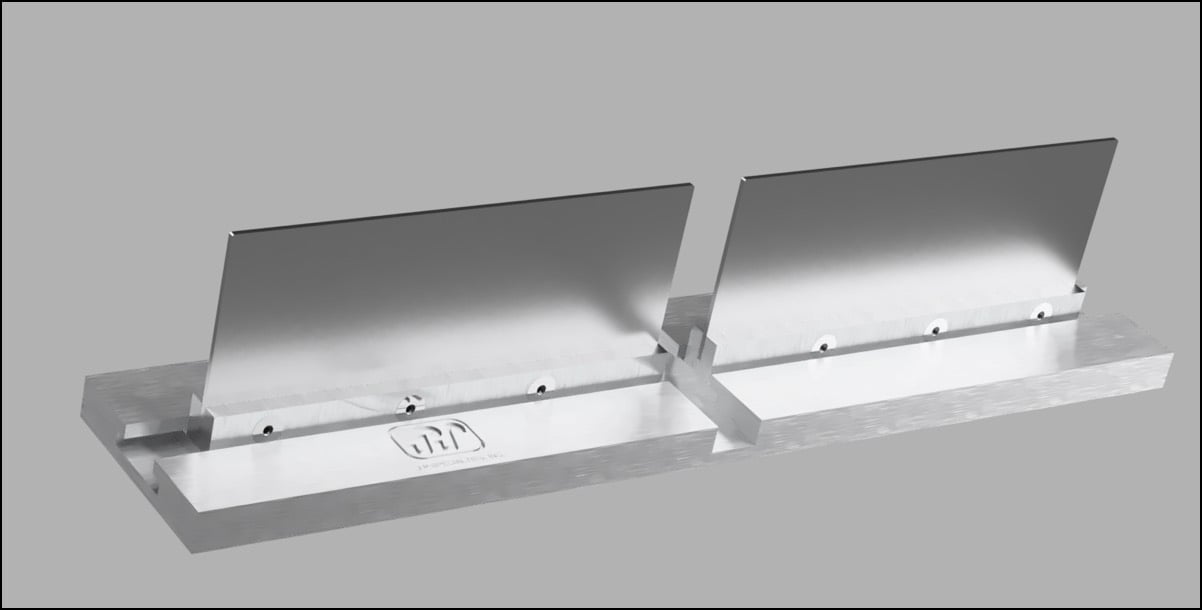

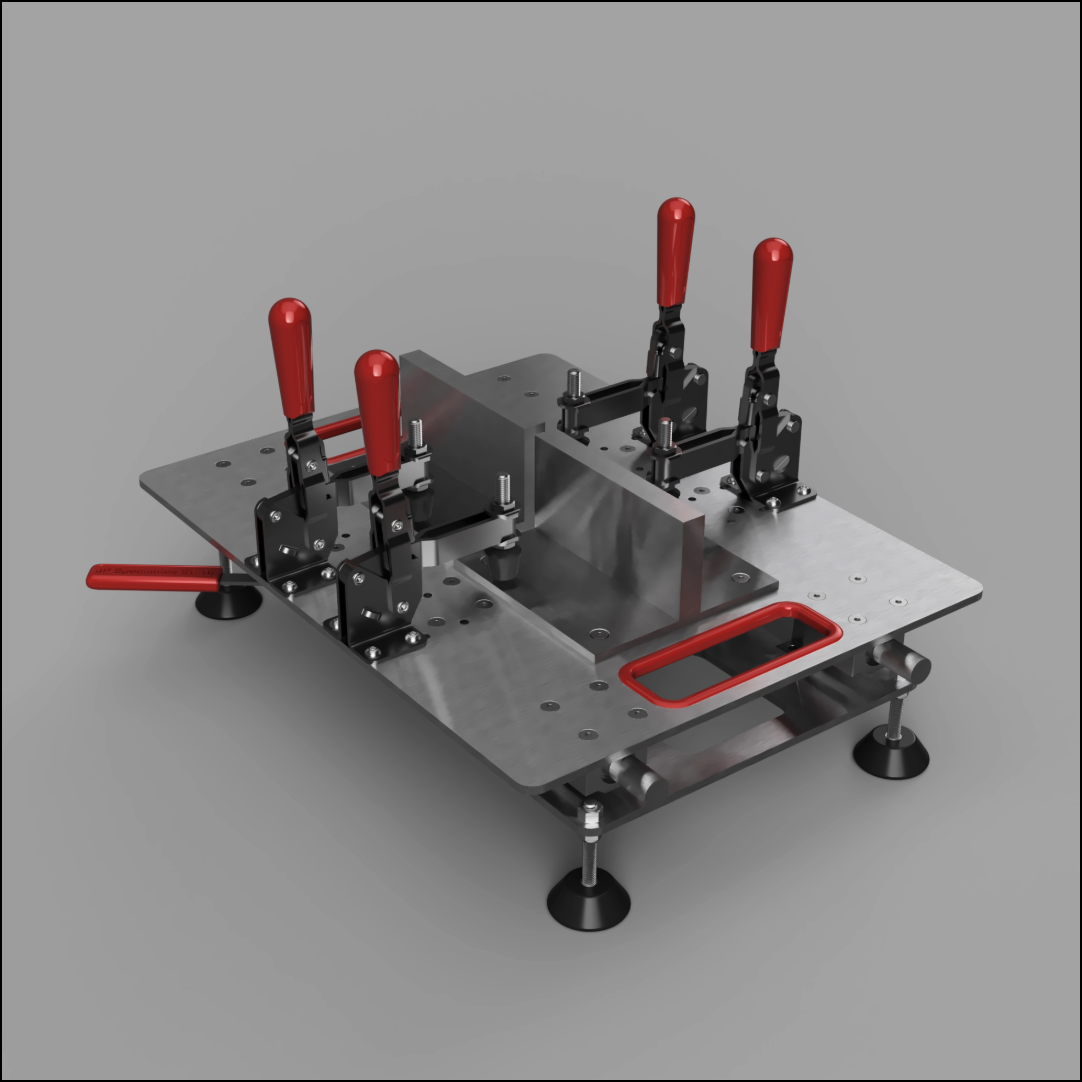

ST-10® Series 2 Waterstop Splicing Table

The ST-10® was designed and patented by J P Specialties as the perfect solution for producing high-tensile strength, leakproof welds on thermoplastic waterstops such as PVC, HDPE, LDPE, TPER, and TPV. New quality assurance standards in today’s waterstop specifications mandate tensile testing across field welded joints, usually requiring tensile strength of 80% or better of the parent material. Waterstops welded with the ST-10® assures the Contractor that their workmanship will yield results that are conducive to these rigorous requirements. The ST-10® is also an extreme labor saver, taking a two-man job — welding waterstop — and taking it down to just one man.- Easy to use

- Aligns the waterstop

- Portable, lightweight

- Weather resistant

- Minimizes fumes (maximizes safety)

- High tensile strength welds

- Welds under pressure, eliminating air bubbles

- Welds 4", 6", 9", and 12" waterstops

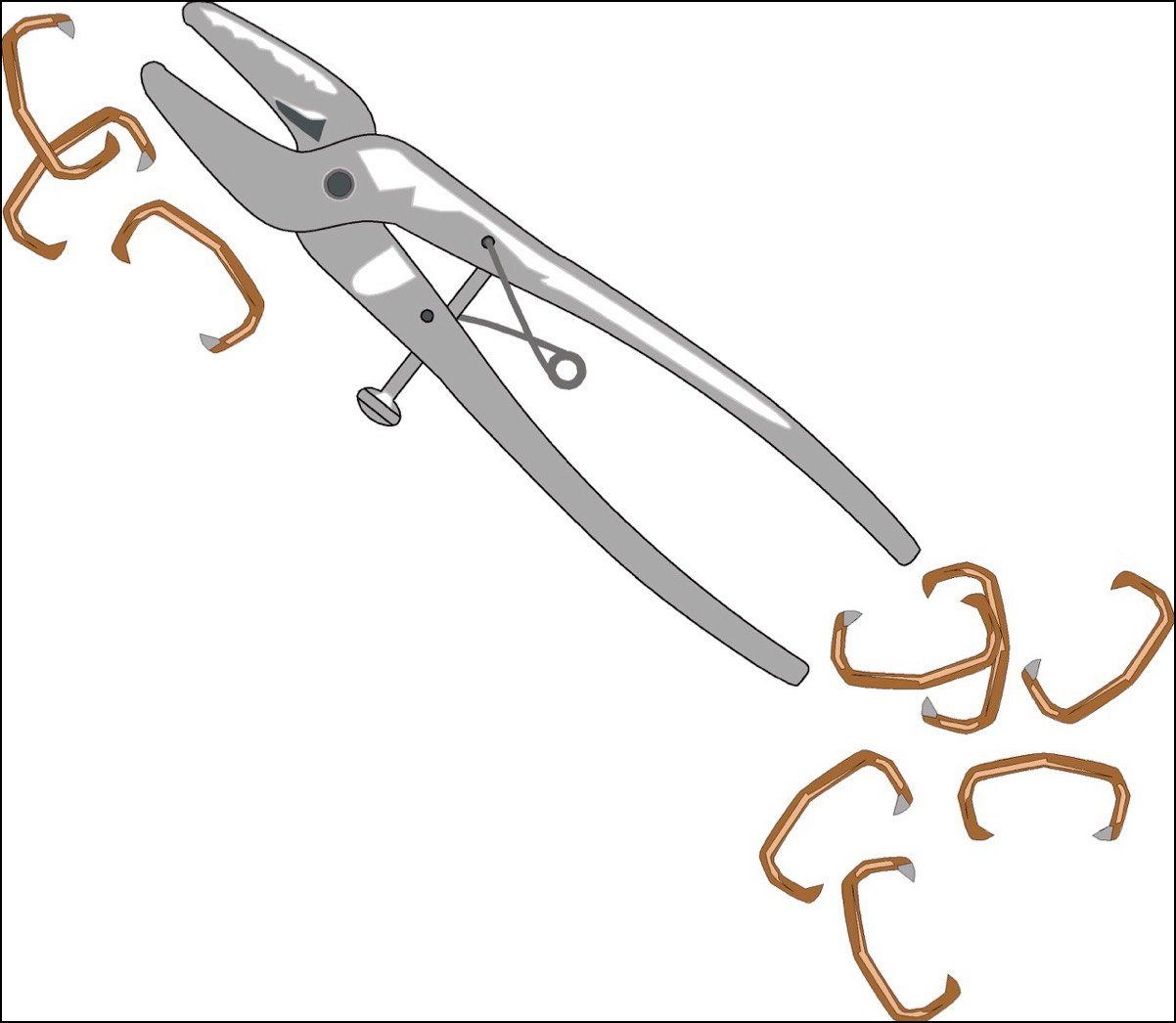

Hog Ring Pliers and Hog Rings

Waterstop Hog RingsCopper-clad, hill-shaped, size #3 hog rings fits every Earth Shield® TPV, PVC, and HDPE Waterstop profiles (as well as most other brands) with equal ease. Used to lash waterstop to the reinforcing steel during installation.

11101 part number

Waterstop Hog Ring Pliers

A durable, lightweight tool with unique torsion spring for ease of use and set screw to ensure perfect hog ring closure every time.

11100 part number

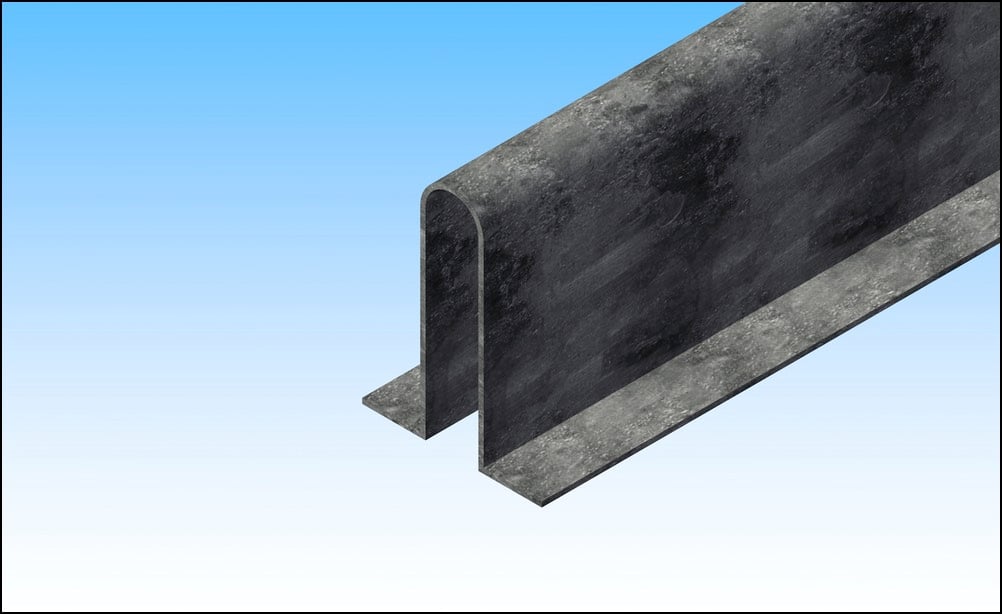

Waterstop Protector

Waterstop Protector protects embedded waterstop for extended periods of time. The protector fits most waterstop profiles and is constructed with heavy-duty, 20 gauge, electro-galvanized steel. Other grades, thicknesses, and metals are available, including for CH2M Hill specification.2055EG part number

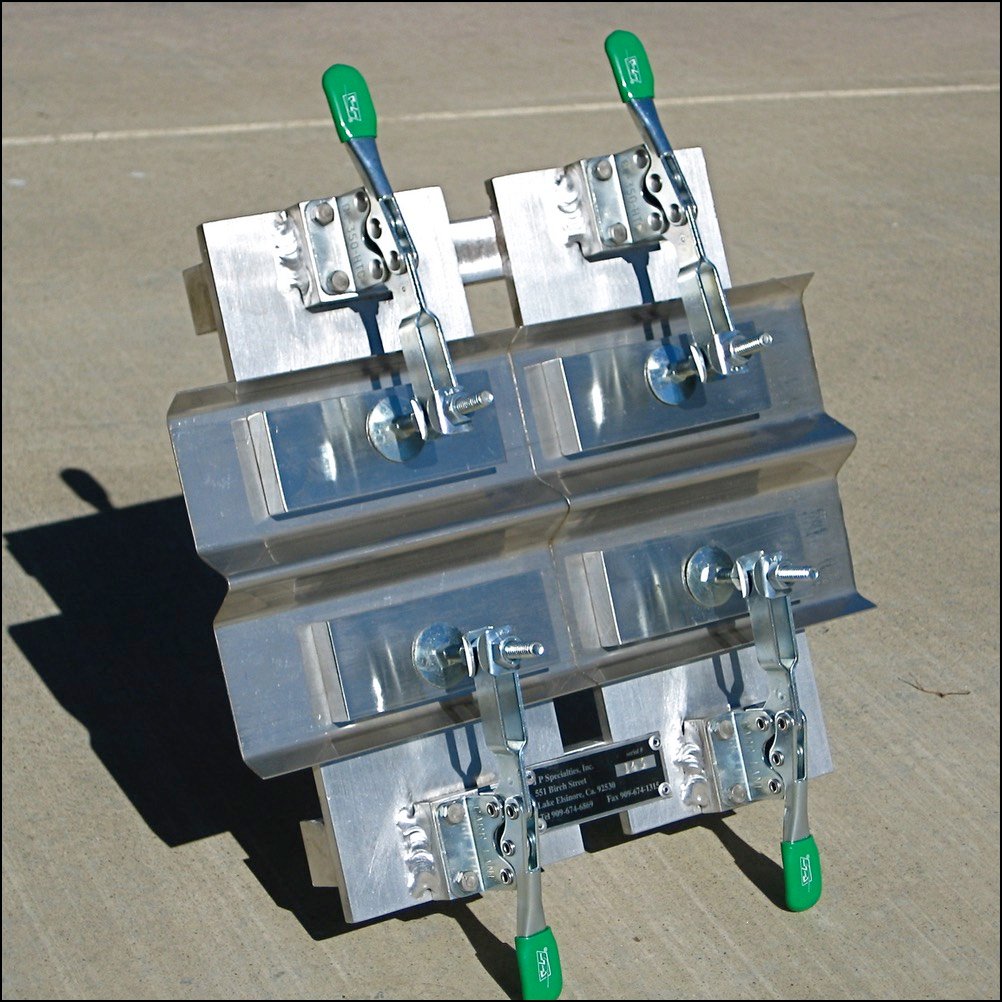

Stainless Steel Waterstop Welding Jig

Our stainless steel waterstop welding jig is designed to perfectly align the straight lengths of Earth Shield® Stainless Steel Waterstop for field fabrication. Includes copper cool bar for heat sink. See the tool in action here.12015 part number

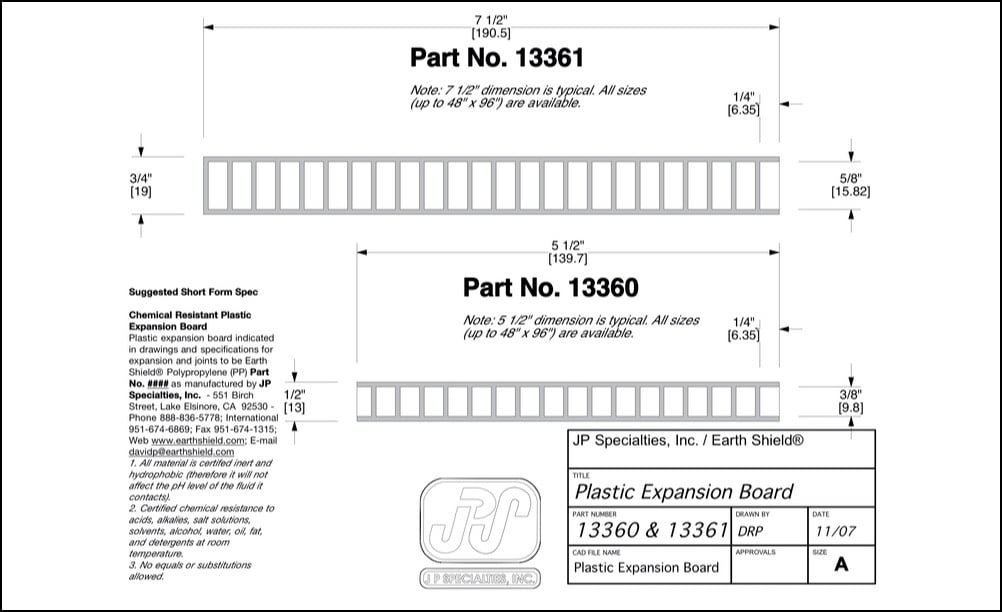

Plastic Expansion Joint Filler Board

Earth Shield® Expansion Board Cap Waterstop is installed on top of conventional expansion board filler or Earth Shield’s own chemical resistant, plastic expansion board. The expansion board acts as the form; therefore, no form splitting is necessary. This greatly accelerates the project schedule and provides a long lasting, attractive finished concrete joint.13360 part number .50” x 48” x 96” board; factory cut to desired depth at no charge to customer

13361 part number .75” x 48” x 96” board; factory cut to desired depth at no charge to customer